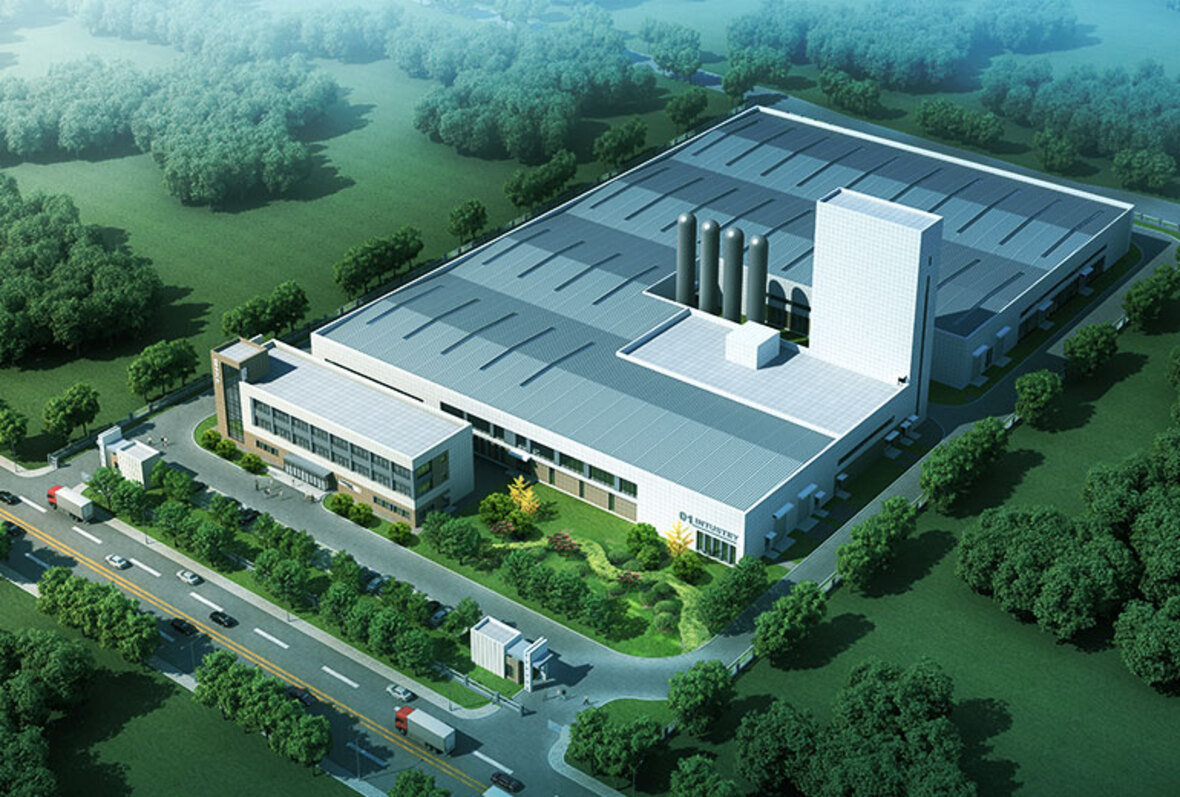

Polyester chip production line for food-grade recyclable bottles

In 2006, with the special approval by relevant authorities, INCOM established a polyester chip production line for food-grade recyclable bottles, with an annual processing capacity of 50,000 tons of waste PET beverage bottles (equivalent to 2.2 billion waste PET beverage bottles), annual output of 30,000 tons of recyclable clean PET fragments, and 20,000 tons of recyclable ultra-clean polyester chips, properly filling the gap of China’s food-grade recyclable polyester chip market at that time. INCOM is one of China’s second batch of circular economy pilot units and standing directors of China Packaging Federation.

Sustainable cycle model

-

Systematic recycling

Systematic recycling

Using intelligent self-service recycling networks and other channels, INCOM has built more secure and reliable systematic recycling networks. -

Professional sorting

Professional sorting

In order to ensure the unity and controllability of raw materials for production, INCOM has established a modern waste PET bottle recycling, sorting and packing center for professional and efficient sorting with modern production equipment, thus forming a large-scale front-end recycling system and s -

Deep cleaning

Deep cleaning

It focuses on physical cleaning, in conjunction with food-grade cleaning agents. Impurities are removed gradually through multi-stage repeated cleaning and separation (e.g. density separation, winnowing separation and magnetic separation), to finally obtain the clean polyester chips that meet qualit -

Deep purification

Deep purification

Using clean PET chips as raw materials, volatile impurities are efficiently removed by the 12-screw ring extruder, and small-sized organic impurities are further removed through solid-phase polycondensation, so that final products meet the food-grade hygiene and safety requirements. All production o

Service case

Leave Message

Leave Message